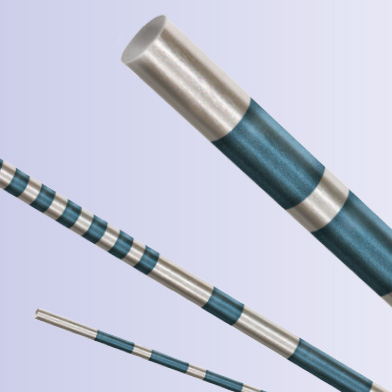

Liquid Silicone Rubber (LSR) and Silicone Transfer Molding (STM) are widely used in the medical device industry for the production of various medical device components such as catheters, tubing, connectors and handles or grips.

The process of LSR molding involves injecting liquid silicone rubber into a mold cavity, often over electrical connections or a circuit board. It is then allowed to cure or solidify into the desired shape. This process is primarily suitable for components that are less sensitive to pressure or impact.

Benefit: In general, LSR molding is a faster and more productive process when speed is an advantage

Silicone transfer molding is another manufacturing process used in the medical device industry. It is similar to LSR molding but focuses on more delicate electrical connections or instruments. It is a 2-step process that involves the manual molding of components into shape.

Benefit: This is a more gentle process, specific to for example impact or pressure sensitive elements on PC boards or delicate cables.

View product website